Understanding SLA 3D Printing and Its Advantages

SLA 3D printing, also known as stereolithography, is a form of 3D printing technology that creates highly accurate and detailed objects layer by layer using a UV laser. The process involves melting and solidifying resin into thin layers until the final object is completed.

One of the main advantages of SLA 3D printing is its precision. The technology is capable of producing objects with intricate details and highly accurate dimensions, making it ideal for creating objects with complex geometries. This level of precision is difficult to achieve with other forms of 3D printing, such as FDM or SLS.

Another advantage of SLA 3D printing is its ability to create smooth surfaces and fine details. The layer height in SLA 3D printing is typically less than 0.1mm, which allows for a high level of detail in the final object. This is particularly useful for creating objects with curved surfaces or filigree structures.

Additionally, SLA 3D printing is capable of producing objects with a high level of transparency or translucency. This makes it a popular choice for creating objects such as light fixtures, medical devices, and other products that require clear or translucent materials.

SLA 3D printing is also a relatively fast process compared to traditional manufacturing methods. The printing process itself typically takes several hours, but it is much faster than other forms of 3D printing. This makes it an ideal method for creating prototypes or small runs of products.

Overall, SLA 3D printing is a highly precise and versatile form of 3D printing technology that offers a range of benefits for creating complex, detailed, and transparent objects. Its accuracy, smooth finish, and speed make it a popular choice for a wide range of applications across industries.

Top Industries Benefiting from SLA 3D Printing Technology

SLA 3D printing technology has become an essential tool for various industries as it offers numerous benefits over traditional manufacturing methods. Here are the top industries that have been benefiting from SLA 3D printing technology:

1. Aerospace Industry

The aerospace industry requires parts with high precision, accuracy, and complexity. SLA 3D printing technology enables the production of these parts with minimal wastage and maximum efficiency. It can also produce lightweight, intricate parts with better strength-to-weight ratio and durability than traditional methods.

2. Medical Industry

SLA 3D printing technology has revolutionized the medical industry by enabling the production of complex medical implants with high precision, accuracy, and efficiency. It can produce customized prosthetics, dental implants, and surgical tools with faster turnaround times and better outcomes for patients.

3. Automotive Industry

The automotive industry requires parts and components that are durable, precise, and excellent in performance. SLA 3D printing technology can produce high-strength, temperature-resistant, and lightweight parts with excellent surface finish and dimensional accuracy. It can also enable the production of customized car parts and accessories with faster turnaround times and reduced costs.

4. Jewelry Industry

The jewelry industry has embraced SLA 3D printing technology to produce high-quality, intricate, and customized jewelry designs with excellent surface finish and accuracy. It can create complex geometries, fine details, and textures that traditional manufacturing methods cannot replicate. SLA 3D printing technology also enables jewelers to produce prototypes and mockups before finalizing designs.

5. Education Industry

SLA 3D printing technology has transformed the education industry by enabling hands-on, experiential learning opportunities for students. It can produce 3D models, prototypes, and parts for engineering, architecture, and science courses. Students can design, create, and test their ideas, concepts, and projects with greater creativity and innovation.

In conclusion, SLA 3D printing technology has wide-ranging applications and benefits for various industries. Its ability to produce high-precision, customized, and intricate parts with minimal wastage and maximum efficiency has made it an essential tool for modern manufacturing and design processes.

Tips for Choosing the Best SLA 3D Printer for Your Business

If you're considering investing in an SLA 3D printer for your business, here are some key factors to consider:

- Print Quality: Look for a printer with a high precision laser that is capable of producing highly detailed prints with incredibly smooth surfaces.

- Printing Speed: Choose a printer that balances speed with quality. Some printers may sacrifice detail for speed, while others may take too long to produce a single print.

- Build Volume: Consider the size of the objects you will be printing and select a printer with a large enough build platform to accommodate your needs.

- Materials: Different SLA 3D printers are compatible with different materials, so consider the materials you plan to print with and choose a printer that is compatible with those materials.

- Price: 3D printers can range in price from a few hundred dollars to tens of thousands of dollars. Set a budget for yourself and choose a printer that meets your needs and your budget.

- Support: Consider the level of support you will receive from the manufacturer or dealer. Will they provide technical support, training, and software updates?

By carefully considering these factors, you can find the best SLA 3D printer for your business needs.

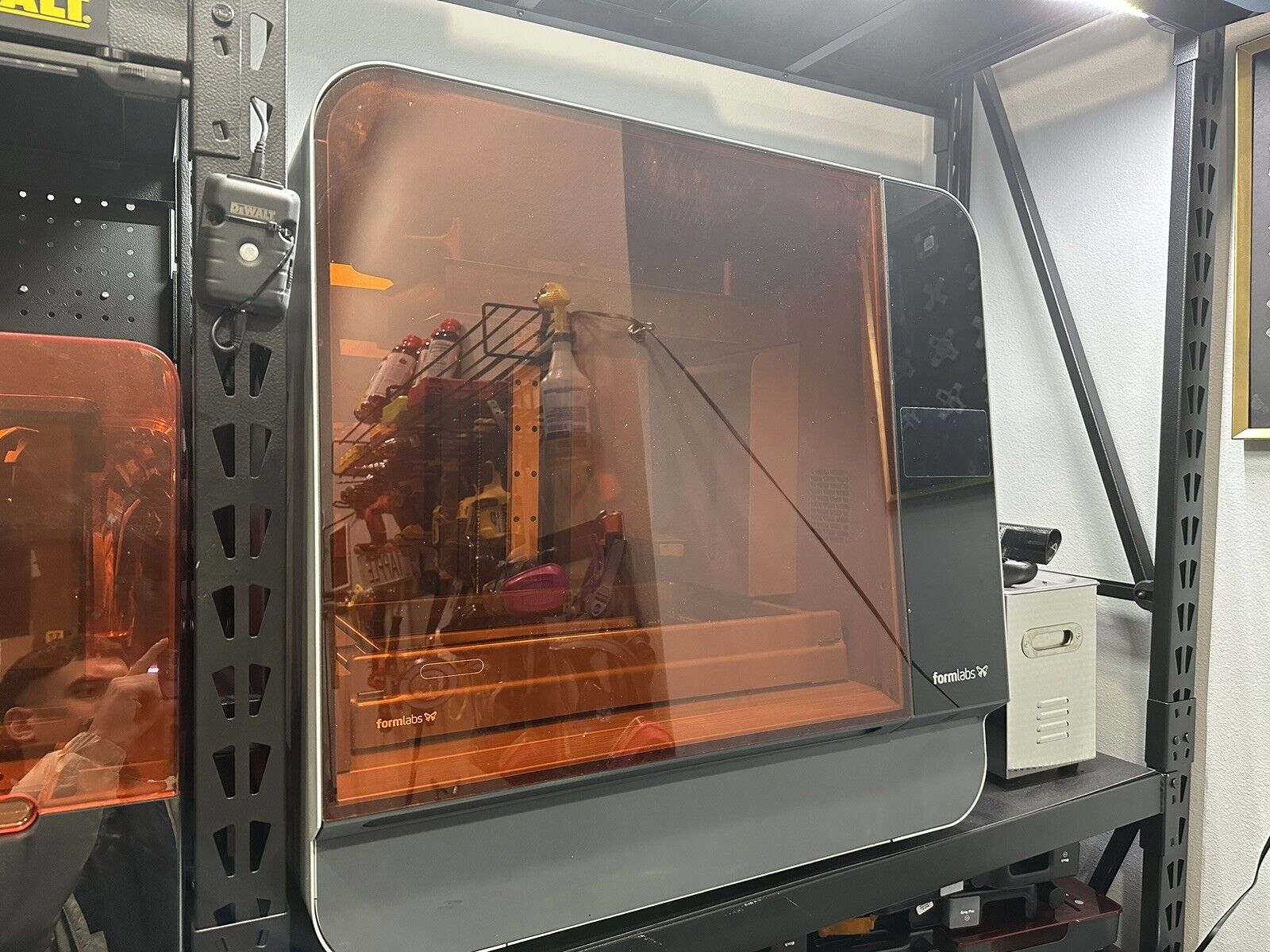

Formlabs Form 3L 3D SLA Printer

Experience the next level of precision and efficiency with the Formlabs Form 3L 3D SLA Printer

Product information

€5,917.63

Product Review Score

4.61 out of 5 stars

103 reviews