What Are SLS 3D Printers?

SLS (Selective Laser Sintering) 3D printers are a type of 3D printer that use a high-powered laser to selectively fuse small particles of plastic, metal, or ceramic powder into a three-dimensional object. The process begins with a bed of powder material that is spread out evenly. The SLS printer then scans the material with a laser, selectively melting or sintering specific areas of the powder layer to create a solid structure. This process is repeated layer by layer until the final object is fully formed.

The advantage of using SLS 3D printers is that they can produce objects with complex geometries that are difficult or impossible to create with traditional manufacturing methods. Additionally, SLS printing does not require support structures, as the mesh of powder acts as a natural support for the printed object as it is being built. SLS printing also allows for the use of a wide range of materials, making it a versatile technology for many different applications.

Some common uses for SLS 3D printers include creating prototypes, model making, producing medical implants, and manufacturing small and intricate parts. These printers are also used in the aerospace and automotive industries to create lightweight and durable parts.

Overall, SLS 3D printers offer a high level of precision, accuracy, and versatility, making them an excellent tool for bringing complex designs to life.

Advantages and Limitations of Using SLS 3D Printers

SLS 3D printers are a popular choice in the additive manufacturing industry. These printers use a laser to sinter small particles of material, such as nylon or metal, to create accurate and detailed 3D objects. While SLS 3D printing has many advantages, it also has some limitations to consider.

Advantages:

- Wide range of materials: SLS 3D printers can use a variety of materials, including nylon, polystyrene, and metal powders. This allows for greater flexibility in material selection for various 3D printing applications.

- No support structures needed: SLS printing does not need support structures, as the unsintered powder acts as support for the object being printed. This reduces the time and expense of removing support structures from the final print.

- Highly detailed prints: SLS printing produces highly detailed prints with excellent surface finish. It can produce complex shapes with intricate details not possible with other printing methods.

- Highly accurate: SLS printing produces highly accurate prints with tolerances as low as 0.1 mm. This makes it ideal for creating functional prototypes and final products requiring precision.

Limitations:

- High cost: SLS 3D printers are generally more expensive than other 3D printers, making them less accessible for small businesses and hobbyists.

- Longer print times: While SLS printing does not require support structures, it can take longer to print objects due to the time required for sintering layers of material. This can increase production times and costs.

- Post-processing required: SLS prints require post-processing, which includes removing the unsintered powder and cleaning the final print. This can be time-consuming and add to the overall cost of printing.

- Limited resolution: SLS printing has a lower resolution than other 3D printing methods such as SLA or DLP. This can limit the level of detail and precision that can be achieved in the final print.

In conclusion, SLS 3D printing is a highly effective and versatile method of additive manufacturing that has many advantages. However, it also has some limitations and considerations to take into account. It is important to assess the specific requirements of a project and weigh the advantages and limitations of using SLS printers before deciding on a printing method.

Applications and Future of SLS 3D Printing Technology

SLS 3D printing technology has revolutionized the way we manufacture and produce products. The flexibility and versatility of this printing method have opened up new avenues for innovation and creativity. Here are some of the applications and potential future developments of SLS 3D printing technology:

Applications of SLS 3D Printing Technology

Manufacturing

SLS 3D printing technology has already been used to create a range of products, including automotive parts, aerospace components, and medical devices. The ability to create complex geometries, combined with the durability and functionality of the final product, makes SLS 3D printing an ideal manufacturing solution in many industries.

Prototyping

SLS 3D printing technology is used extensively in the prototyping stage of product design. The ability to create accurate prototypes quickly and cost-effectively allows designers to refine and perfect their designs before they go into production.

Art and Design

SLS 3D printing technology has also opened up avenues for artistic expression and design. It allows artists and designers to create unique, intricate and complex designs that would be impossible to produce using traditional manufacturing techniques.

Future Developments in SLS 3D Printing Technology

Improved Materials

One of the biggest areas of development in SLS 3D printing technology is the continued improvement of materials. As new materials become available, the potential applications for SLS 3D printing technology will continue to expand.

Increased Print Speeds

One of the drawbacks of SLS 3D printing technology is the relatively slow print speeds. However, ongoing research and development are exploring ways to increase print speeds, making this technology even more efficient and cost-effective.

Integration with Other Technologies

SLS 3D printing technology is also being explored for integrated manufacturing processes that utilize robotics, artificial intelligence, and other technologies. This could create a fully automated manufacturing process that is faster, more efficient, and more cost-effective than current methods.

In conclusion, SLS 3D printing technology offers significant potential for manufacturing, prototyping, design, and artistic expression. While there are still several challenges to overcome, ongoing research and development will continue to improve the technology's capabilities and expand its applications.

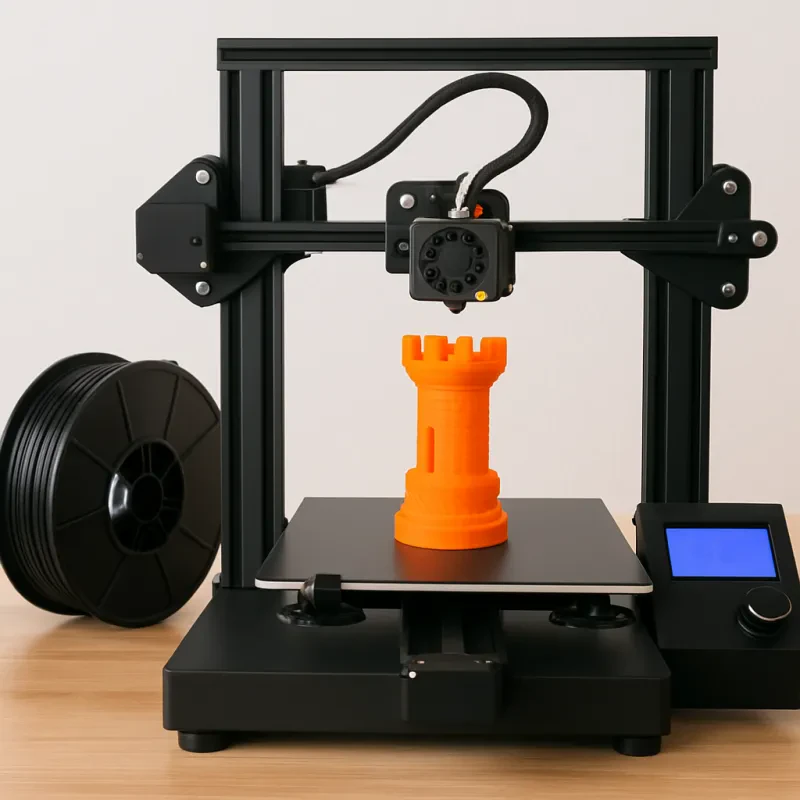

Creality K1C 3D Printer - 600mm/s Speed, AI Camera

Experience rapid printing speeds and enhanced precision with the cutting-edge AI camera technology of the Creality K1C 3D Printer

Product information

$673.07

Product Review Score

4.1 out of 5 stars

190 reviews