Understanding the Basics of ABS Filaments: What You Need to Know

ABS (Acrylonitrile Butadiene Styrene) is a common thermoplastic material used in 3D printing. It is widely used in various industries, including automotive, aerospace, and consumer goods. In this article, we will discuss the basics of ABS filaments, including its properties, applications, and printing tips.

Properties of ABS Filaments

ABS is a strong, lightweight, and durable material that is resistant to impact, chemicals, and heat. ABS filaments are available in a wide range of colors and can be easily modified to achieve different properties. It is also a relatively inexpensive material compared to other alternatives.

Applications of ABS Filaments

ABS is extensively used in the automotive industry for the production of parts such as dashboards, housing, and bumpers. It is also used in the aerospace industry for the production of interior parts such as cabin walls, cowlings, and seating components. ABS is widely used in the consumer goods industry for the production of toys, cases, and packaging materials.

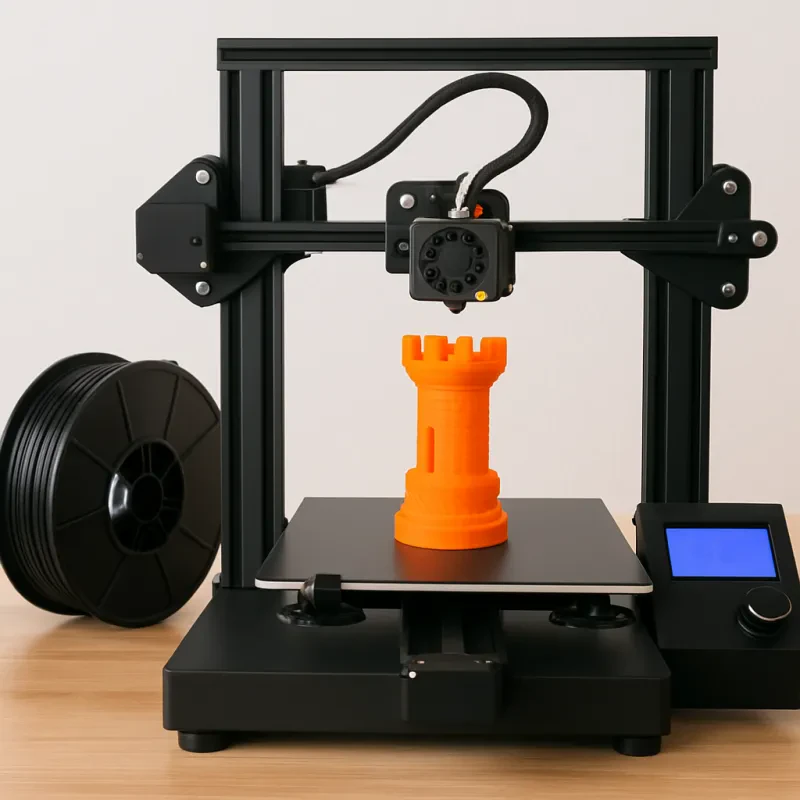

Printing Tips for ABS Filaments

ABS has a high melting point and requires a heated build plate to prevent warping and cracking during printing. The ideal temperature range for printing ABS is between 230°C and 260°C. A high-temperature extruder is recommended for printing ABS to ensure smooth and consistent flow. It is also recommended to use an enclosure to maintain a consistent temperature and prevent drafts during printing.

In conclusion, ABS filaments are a popular choice for 3D printing, thanks to their strength, versatility, and affordability. Using the right printing techniques can help you achieve high-quality prints with ABS filaments. So, if you're looking for a durable and reliable material for your next 3D printing project, ABS filament might be the perfect choice for you.

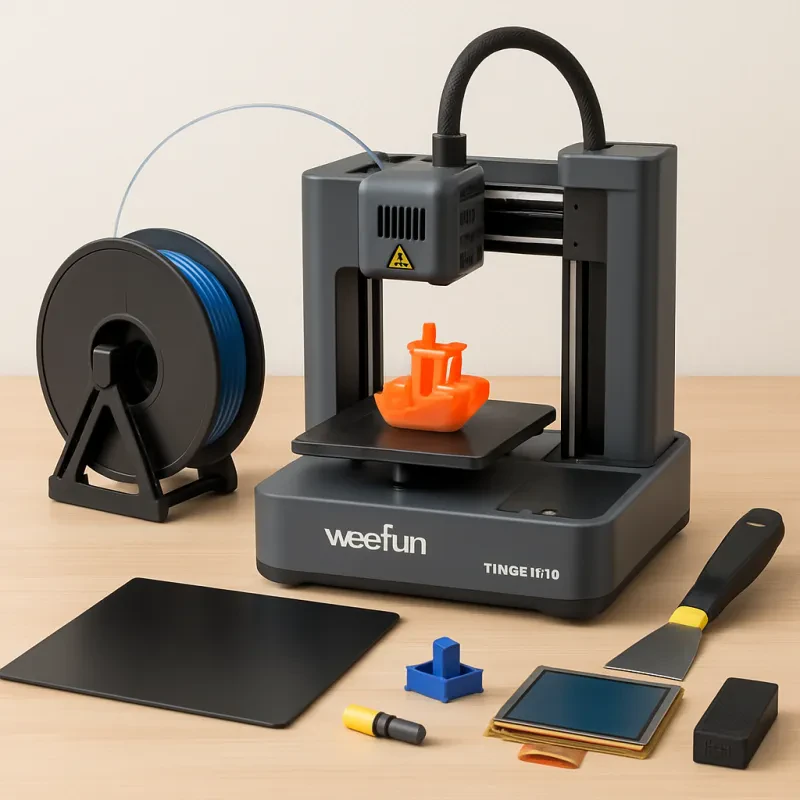

Choosing the Best ABS Filament for Your 3D Printing Needs

When it comes to 3D printing with ABS filament, choosing the right one for your particular project is essential. Here are some factors to consider when selecting the best ABS filament for your 3D printing needs:

- Diameter: ABS filament typically comes in two diameters: 1.75mm and 3mm. Make sure you select the diameter that's compatible with your 3D printer.

- Colors: ABS filament comes in a wide variety of colors, allowing you to choose the perfect shade for your project. If you need a specific color that's not available, you may need to consider mixing primary colors to create a custom shade.

- Strength: ABS filament is known for its strength and durability. However, some ABS filaments are more resistant to breaking and warping than others. Make sure to select a filament that's strong enough for your project.

- Flexibility: If your project requires flexibility, you'll need to look for an ABS filament that's more pliable. Some ABS filaments are more rigid and brittle, so choose accordingly.

- Temperature resistance: ABS filament can withstand high temperatures, making it a great option for projects that require heat resistance. However, not all ABS filaments have the same level of heat tolerance, so make sure to check the specifications before selecting a filament for a high-heat project.

By considering these factors when selecting an ABS filament, you can ensure that your 3D printing project is a success. Remember to always read the specifications and use the correct settings in your 3D printer to achieve the best results.

Tips and Tricks for Successfully Printing with ABS Filaments

ABS filaments are a popular 3D printing material that are known for their strength and durability. However, printing with ABS filaments can be tricky, as they have a tendency to warp and shrink during the printing process. Here are some tips and tricks for successfully printing with ABS filaments.

1. Use a Heated Bed

One of the biggest challenges when printing with ABS filament is keeping the print bed warm enough to prevent warping. ABS filaments typically require a bed temperature of around 100 degrees Celsius, so make sure your printer has a heated bed. Additionally, make sure you calibrate the bed level properly, as this can affect warping.

2. Enclose the Printer

Another way to prevent warping is to enclose your printer and create a stable environment with consistent temperature and humidity. You can create an enclosure using plexiglass or similar material, and use a small heater or fan to maintain a constant temperature.

3. Use a Raft

A raft is a thin layer of material that is printed beneath your model to prevent warping. When you use a raft, the print adheres to the raft instead of the bed, which can help keep the model flat. Make sure you adjust the spacing between the raft and the model so that it is close enough to provide a solid base, but not so close that it fuses together.

4. Print Slowly

ABS filament requires a slower printing speed than other filaments. This is because ABS tends to melt and warp at a higher temperature, so printing slowly gives the material time to cool and settle into place. It's also a good idea to adjust the layer height to a smaller size, as this can improve the level of detail in the print.

5. Use an Enclosure During Cooling

After printing, it's important to let your ABS filament cool down slowly. This can be done by keeping the print inside the enclosure until it reaches room temperature. Taking the print out too soon can cause it to warp or crack.

By following these tips and tricks, you should be able to successfully print with ABS filaments. Remember, with any new 3D printing material, it takes some trial and error to get the settings right. Don't be afraid to experiment with different temperatures and settings to find what works best for your specific printer and model.

ABS Filament for FDM 3D Printers - White

ABS Filament for FDM 3D Printers in White, Providing High-Quality Prints and Precise Details

Product information

£21.99 £15.83

Product Review Score

4.32 out of 5 stars

199 reviews