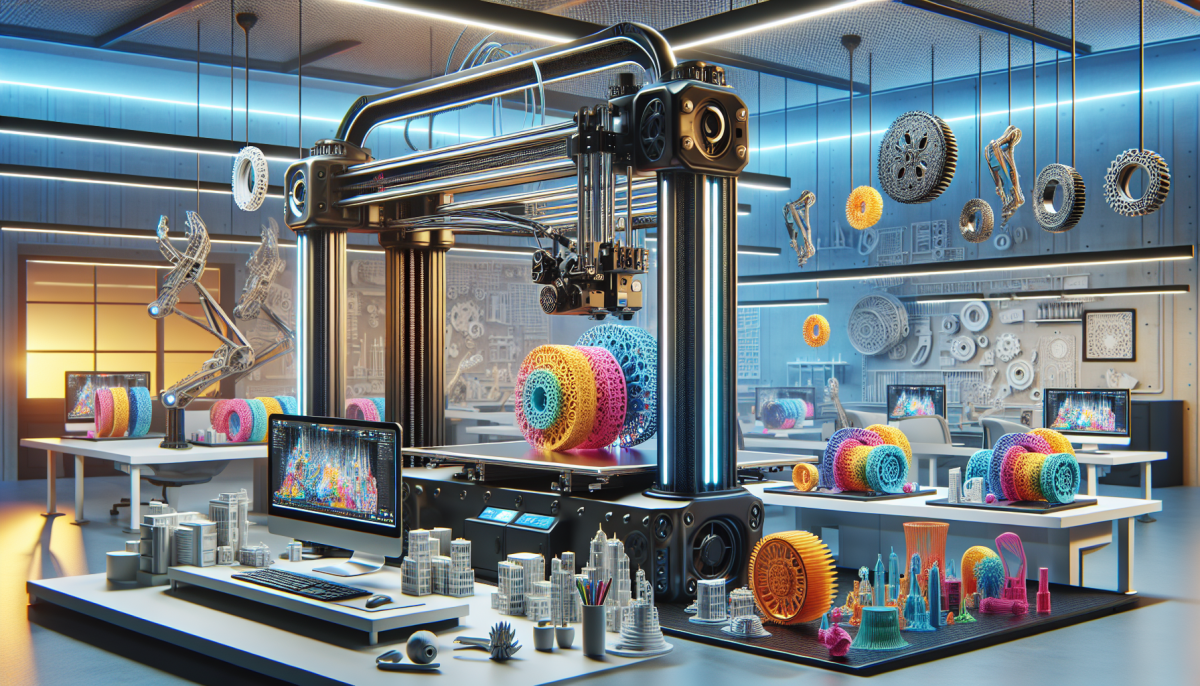

Understanding the Capabilities and Limitations of 3D Printers: A Comprehensive Overview

3D printing technology has gained immense popularity in recent years due to its incredible potential to revolutionize the manufacturing industry. These printers have made it possible to create complex objects with intricate designs and shapes, which were previously impossible to achieve with traditional manufacturing methods.

However, like any other technology, 3D printers have their own set of capabilities and limitations. To fully understand what you can and can't do with a 3D printer, it's essential to have a comprehensive overview of the technology.

What 3D Printers Can Do

3D printers are capable of producing a wide range of objects, including functional parts, prototypes, and even artistic creations. Below are some of the things that 3D printers can do.

Produce Complex Shapes

3D printers can produce objects with highly complex geometries, which were previously impossible to achieve with traditional manufacturing methods. With 3D printing, you can create objects with intricate curves, internal cavities, and even moving parts.

Create Custom Objects

3D printing allows for the creation of custom objects that can be tailored to specific needs. This means that you can create objects that perfectly fit into a particular space or perform a unique function.

Print Multiple Objects at Once

Most 3D printers are capable of printing multiple objects at once, making it a highly efficient manufacturing method. This is particularly useful when you need to produce a large number of identical parts quickly.

The Limitations of 3D Printers

While 3D printers are incredibly versatile, they also have some limitations. Here are some of the things that 3D printers can't do.

Print Large Objects

Most 3D printers have limited build volumes, which means that they can only produce relatively small objects. If you need to print large objects, you may need to print them in multiple parts and then assemble them later.

Produce Certain Materials

3D printers can only produce objects with certain materials, such as plastics, metals, and ceramics. They cannot produce objects made from materials that are too soft or too brittle.

Produce Certain Surface Finishes

3D printers produce objects with a distinct layered texture, which may not be suitable for certain applications. For instance, if you need to produce objects with a smooth finish, you may need to post-process them to remove the layer lines.

Conclusion

3D printing is a highly versatile technology that has the potential to revolutionize the manufacturing industry. By understanding the capabilities and limitations of 3D printers, you can make informed decisions about how to use this technology to its fullest potential.

The Advantages of Using 3D Printing in Manufacturing: Case Studies and Examples

3D printing, also known as additive manufacturing, has significantly revolutionized the manufacturing industry. Compared to traditional manufacturing methods, 3D printing offers numerous advantages that make it a preferred choice for many manufacturers. Here are some case studies and examples that demonstrate the advantages of using 3D printing in manufacturing:

Reduced Costs and Production Time

The use of 3D printing has proven to be a cost-effective option for many businesses. For example, aircraft parts manufacturer Airbus was able to save over €60,000 per year by using 3D printing to produce a small part for the A350 XWB commercial plane. Similarly, Porsche was able to reduce its production time from 90 days to just 10 days for a single component of its 911 GT3 Cup racing car by utilizing 3D printing technology.

Customization and Design Freedom

One of the significant advantages of 3D printing is that it offers designers complete freedom to create complex geometries that would be impossible or expensive to produce with traditional manufacturing methods. The technology allows for customization of specific parts to meet individual requirements, such as medical implants. Orthopedic implants manufacturer, LimaCorporate, uses 3D printing to create customized implants tailored to individual patients’ anatomy, resulting in better patient outcomes.

Reduced Waste and Environmental Impact

3D printing helps reduce waste and environmental impact by using fewer materials than traditional manufacturing methods. A notable example is General Electric's LEAP aircraft engine. GE's 3D printing process cut the weight of the engine by around 1000 pounds, saving over 15,000 gallons of fuel per year and significantly reducing carbon emissions.

Increased Supply Chain Efficiency

3D printing helps improve supply chain efficiency by reducing inventory requirements and facilitating distributed manufacturing. Major automotive parts manufacturer, Continental, uses 3D printing to produce small parts for its brake systems in several locations across the globe, reducing shipping costs and inventory in the process.

In conclusion, the above examples demonstrate that 3D printing offers unparalleled advantages for both large and small manufacturers. The technology has the potential to significantly improve manufacturing efficiency while also reducing costs and improving environmental sustainability. As 3D printing technology advances, we can expect to see even greater benefits for those who choose to adopt it.

Exploring the Future of 3D Printing: Trends, Innovations, and Possibilities

3D printing has come a long way since its inception in the late 1980s. From the early days of rapid prototyping to today's multifaceted applications, 3D printing has become an integral part of various industries. The future of 3D printing looks bright, with several trends, innovations, and possibilities that we will explore in this article.

Trends

One trend in 3D printing is the increasing demand for more eco-friendly and sustainable materials. The use of biodegradable materials such as PLA (polylactic acid) and PHA (polyhydroxyalkanoate) is gaining popularity due to environmental concerns and the need for sustainable solutions.

Another trend in 3D printing is the growth of metal 3D printing. The use of metal 3D printing has expanded to industries such as aerospace, automotive, and medical where the high strength and durability of metals are critical factors.

Innovations

The innovations in 3D printing are numerous and continue to evolve. One of the most exciting is the development of advanced 3D printing techniques, such as multi-material printing. This technique enables the creation of complex geometries with different materials, which can be useful in applications such as artificial organs and prosthetics.

Another exciting innovation is the use of 3D printing for construction. The development of large-scale 3D printers has made it possible to print whole buildings, reducing construction time and waste while offering greater design flexibility.

Possibilities

As 3D printing technology progresses, the possibilities for its use are endless. One area where 3D printing can make a significant impact is in the medical field. The ability to print prosthetic limbs, artificial organs, and bone replacements could revolutionize the way we approach healthcare.

Another possibility is the use of 3D printing in space exploration. The lack of resources and materials on other planets makes 3D printing an attractive option. NASA has already experimented with 3D printing tools and parts for space missions, and the technology could be crucial in future space exploration efforts.

Conclusion

The future of 3D printing is exciting and full of possibilities. With new trends and innovations emerging daily, we can only imagine the advancements and breakthroughs that lie ahead. From sustainable materials to large-scale construction, 3D printing has already made a significant impact on various industries, and its potential is only just beginning to be realized.

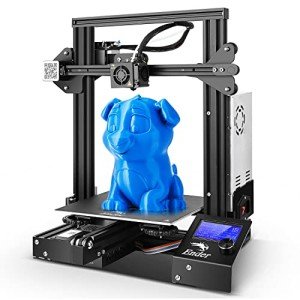

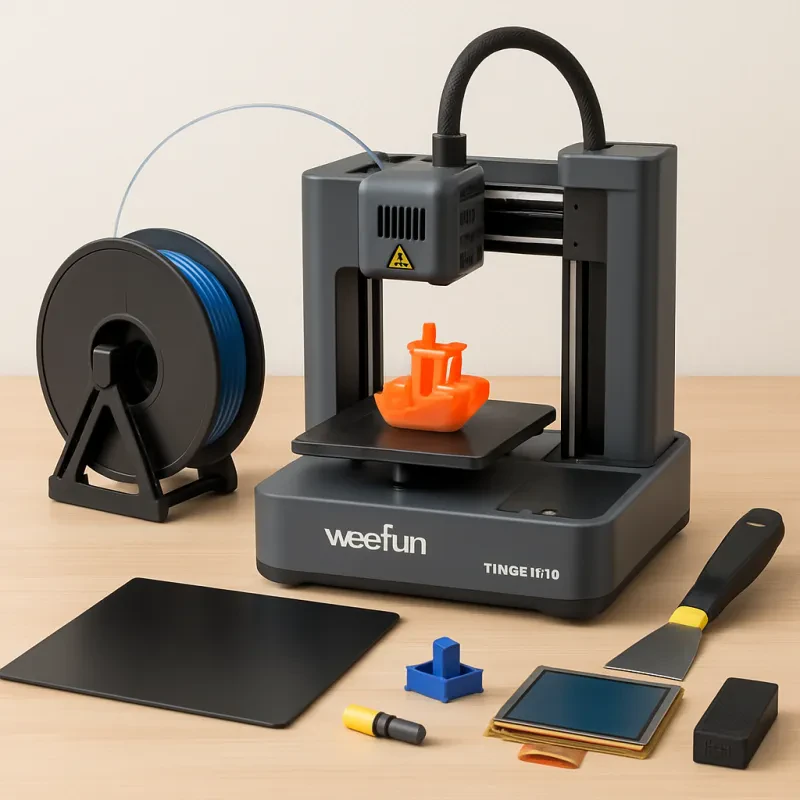

Creality Ender 3 - Fully Open Source 3D Printer

Unlock Your Creative Potential with the Creality Ender 3 Fully Open Source 3D Printer

Product information

$179.00

Product Review Score

4.74 out of 5 stars

54 reviews