PETG, or glycol-modified PET, is a commonly used thermoplastic material in the 3D printing industry. It is a strong, durable, and versatile material that is used for a variety of applications. PETG filaments are made from PET plastic, commonly used in packaging of food and beverages.

PETG has several advantages over other 3D printing filaments like PLA and ABS. PETG is stronger than PLA and more flexible than ABS, making it ideal for printing objects that require both strength and flexibility. It also has better impact resistance than ABS and is more heat resistant than PLA, which makes it suitable for printing parts that need to withstand higher temperatures.

Another notable characteristic of PETG filaments is that they are water-resistant and have excellent dimensional stability, which means that they are less likely to shrink or warp during printing. PETG also has a glossy finish, giving printed objects a sleek and professional look.

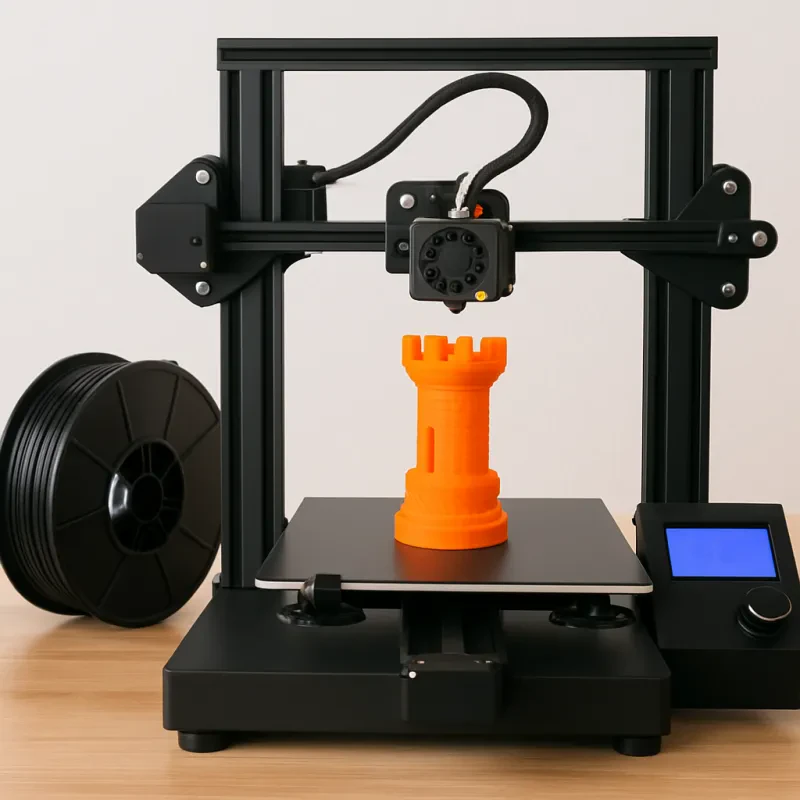

PETG filaments are easy to print with on most 3D printers and do not require a heated bed or an enclosure. The printing temperature for PETG is generally around 220-250°C, and it can be printed at a speed of up to 60 mm/s. PETG filaments also have low odor and do not emit harmful fumes during printing.

In conclusion, PETG filaments are an excellent choice for 3D printing due to their strength, durability, flexibility, and water-resistant properties. Their printing characteristics and glossy finish make them an ideal choice for a wide range of applications, from unique designs and prototypes to functional parts and tools.

Applications of PETG Filaments in 3D Printing: Pros and Cons

When it comes to 3D printing materials, there are a lot of options out there. One filament that has been gaining popularity in recent years is PETG. PETG filaments have several unique qualities that make them ideal for certain applications. In this article, we’ll take a closer look at the pros and cons of using PETG filaments in 3D printing applications.

Pros

Strength and Durability

PETG filaments are known for their strength and durability. They are much stronger than PLA (polylactic acid) and are less likely to break or crack under stress. This makes PETG filaments ideal for applications where strength and durability are important, such as in the creation of mechanical parts or prosthetics.

Flexibility

One of the unique qualities of PETG filaments is that they are flexible. They can be bent and twisted without breaking, making them useful for applications where flexibility is a requirement. This property makes PETG filaments great for creating phone cases or other accessories that need to be flexible and bendable.

Chemical Resistance

PETG filaments are highly resistant to chemicals, including acids, bases, and alcohols. This makes them suitable for use in applications where the printed object will be exposed to harsh chemicals, such as in the chemical industry or when printing laboratory equipment.

Clarity

PETG filaments are known for their clarity, making them a great choice for printing objects that need to be transparent. They are also resistant to yellowing over time, which is important for applications where the object needs to maintain its transparency over a long period of time.

Cons

Temperature Sensitivity

PETG filaments are sensitive to temperature changes. If the temperature is too high, the filament can deform or even melt. This can make it challenging to print with PETG, as the printer has to be carefully calibrated to ensure that the temperature is just right.

Warping

PETG filaments are prone to warping during the printing process. This can lead to objects with uneven surfaces or even cause the print to fail altogether. This can be a frustrating challenge for those new to 3D printing, but can be overcome with proper calibration and print settings.

Hygroscopic

PETG filaments are hygroscopic, which means that they absorb moisture from the air. This can cause the filament to become brittle and difficult to print with. To avoid this, it’s important to store PETG filaments in airtight containers with desiccants to keep them dry.

Cleaning

PETG filaments can be difficult to clean, as they can become sticky and attract dirt and debris. This can be a concern for applications where cleanliness is important, such as in the medical or food industries.

Conclusion

PETG filaments have several unique qualities that make them a great choice for certain 3D printing applications. Their strength, durability, flexibility, chemical resistance, and clarity make them ideal for applications in mechanical engineering, prosthetics, phone cases, and other areas. However, PETG filaments do have some drawbacks, including temperature sensitivity, warping, hygroscopicity, and cleaning difficulties. Ultimately, the decision to use PETG filaments will depend on the specific needs of the project and the expertise of the user in working with this particular filament.

Tips and Recommendations for Using PETG Filaments in Your Aspirational 3D Projects

PETG filaments are a popular choice among 3D printing enthusiasts who seek a balance between strength, flexibility, and ease of use. Here are some tips and recommendations for using PETG filaments in your next 3D printing project.

1. Ensure a Clean Print Surface: PETG filaments tend to stick to the print bed very well, so prepare your 3D printer by thoroughly cleaning the print surface of any residue or debris. You can use a mixture of warm water and dish soap to clean the print bed before starting the print. 2. Avoid Overheating: PETG filaments do not require as high temperatures as other filaments to be printed. Make sure to keep your nozzle temperature between 220-240 degrees Celsius. Overheating may cause your print to deform or warp. 3. Optimize Printer Settings: PETG filaments have unique properties and require some adjustments to print effectively. You can optimize your printer settings by tweaking the print speed, cooling fan speed, and retraction distance. 4. Use a Filament Dryer: PETG filaments tend to absorb moisture from the air, which can lead to delamination and reduced print quality. Using a filament dryer before printing can mitigate this issue. 5. Experiment with Different Colors: PETG filaments come in a range of colors, allowing you to experiment with different hues and shades. You can mix and match different color filaments to create unique and eye-catching prints. 6. Post-Print Processing: PETG filaments can be post-processed to achieve a smoother finish. You can sand the surface with sandpaper to remove any roughness or bumps, or you can apply a coat of epoxy resin to give your print a glossy appearance. 7. Store PETG Filaments Carefully: PETG filaments are sensitive to humidity and should be stored in a dry and cool place away from direct sunlight. Use airtight containers or bags to prevent the filaments from absorbing moisture.

By following these tips and recommendations, you can achieve high-quality, professional-grade prints with PETG filaments. Happy printing!

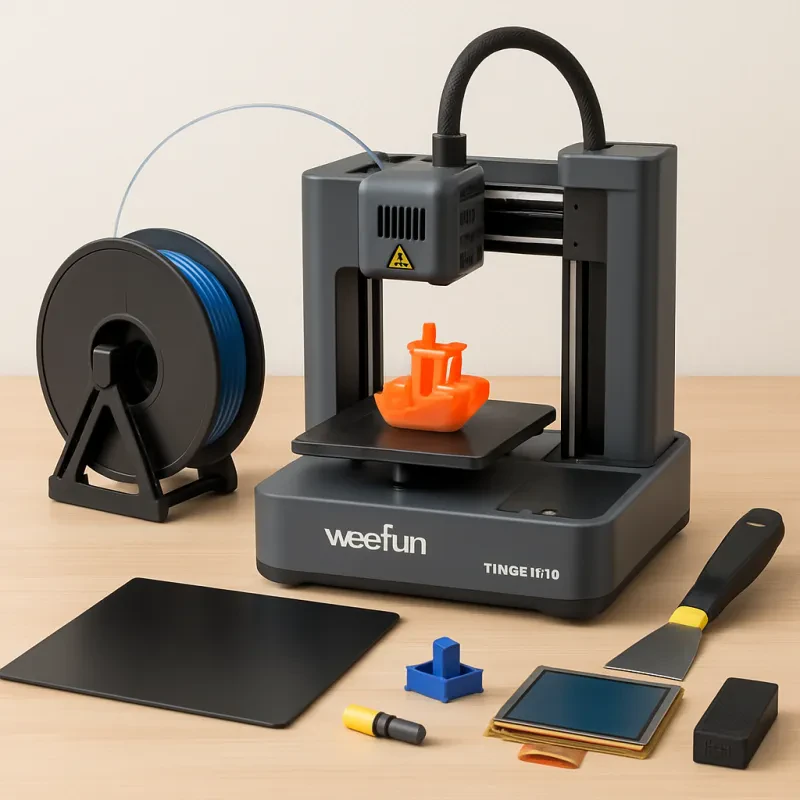

Pinuotu PETG Filament 1.75mm, 1kg Spool

High-quality PETG filament for your 3D printer, suitable for most FDM printers, now available in black

Product information

$17.57

Product Review Score

4.09 out of 5 stars

123 reviews