A Beginner's Guide to 3D Printing Filaments: Understanding the Basics

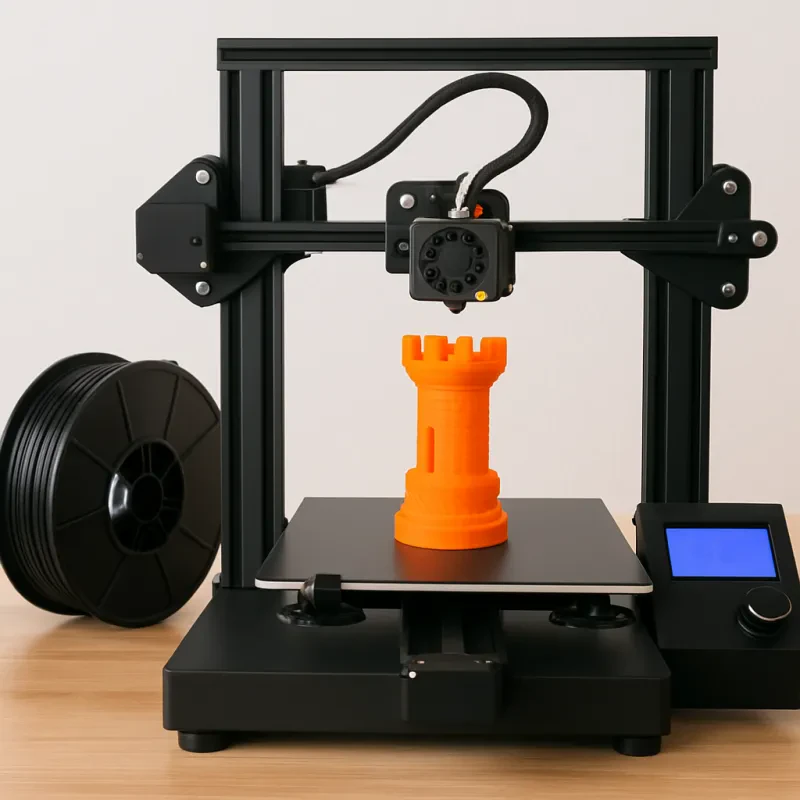

3D printing filaments are the material used in 3D printing to create various objects. Filaments are responsible for the size, strength, flexibility, and texture of the final product. The filament that you choose is crucial to the success of your project, and you need to understand the basics before choosing one.

Types of 3D Printing Filaments

There are several types of filaments available today, and each one serves a specific purpose. Here are some of the most popular types of filaments:

- PLA (Polylactic Acid) - This filament is the most popular choice for beginners because it is easy to use, eco-friendly and biodegradable. It is also versatile and can be used to make a wide range of objects.

- ABS (Acrylonitrile Butadiene Styrene) - This filament is known for its durability and strength. It is used to make objects that require toughness, like car parts, toys, and electronic casings.

- PETG (Polyethylene Terephthalate Glycol) - This filament is similar to ABS but is less prone to warping and is more flexible. It is a great choice for outdoor use because it is resistant to UV rays and moisture.

- TPE (Thermoplastic Elastomer) - This filament is soft and flexible, making it perfect for creating objects like phone cases and rubber mats.

Factors to Consider When Choosing a Filament

Here are some factors that you need to consider when choosing a filament:

- Strength - If you are making objects that require strength and durability, you need to choose a filament that is strong and impact-resistant, like ABS.

- Flexibility - If you are making objects that require flexibility, like phone cases or toys, you need to choose a filament that is flexible, like TPE.

- Temperature Resistance - If you are making objects that will be exposed to high temperatures, like kitchen utensils, you need to choose a filament that is temperature-resistant, like PLA.

- Printability - Some filaments are easier to print than others, so if you are a beginner, you need to choose a filament that is easy to print, like PLA.

Conclusion

Choosing the right filament is crucial to the success of your 3D printing project, and understanding the basics is the first step. Consider the type of object that you are making, the strength, flexibility, temperature resistance, and printability before choosing a filament. With the right filament, you can create objects that are strong, flexible, and perfect for your needs.

Choosing the Right Material: A Comparison of Popular 3D Printing Filaments

When it comes to 3D printing, choosing the right filament material can make all the difference. There are numerous 3D printing filaments available on the market, each with their own unique characteristics and properties. In this article section, we’ll compare some of the most popular 3D printing filaments to help you decide which one is best for your project.

PLA (Polylactic Acid)

PLA is one of the most commonly used 3D printing filaments due to its ease of use and environmentally friendly properties. It is made from plant-based materials such as cornstarch and sugarcane, which make it biodegradable. PLA is known for its strength and durability, and it comes in a wide range of colors. This filament is best suited for projects that require a high level of detail and low warping.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a strong, lightweight filament that is perfect for making structural parts. It is also more flexible than PLA, which makes it ideal for creating parts that require bending and twisting. However, ABS is prone to warping and requires a heated print bed for successful printing. It also emits fumes when melted, so it’s important to use proper ventilation when printing with this filament.

PETG (Polyethylene Terephthalate Glycol)

PETG is a versatile and strong filament that is known for its flexibility and durability. It is resistant to impact, heat, and moisture, making it an excellent choice for outdoor or industrial applications. PETG is also easy to print with and has little to no warping. However, it is more prone to stringing than other filaments and can be difficult to remove from the print bed.

TPU (Thermoplastic Polyurethane)

TPU is a flexible filament that is perfect for creating parts that need to be bendable or squishy. This filament is also known for its abrasion resistance and shock absorption properties. TPU is easy to print with and has excellent layer adhesion, making it ideal for creating parts that require a high level of detail. However, it is more prone to stringing than other filaments and requires a slower print speed.

Nylon

Nylon is a highly versatile filament that is used in a wide range of applications. It is known for its strength, durability, and resistance to wear and tear. Nylon is also highly flexible, making it ideal for creating parts that need to be able to bend and twist. However, nylon is more difficult to print with than other filaments and requires a heated print bed and a higher print temperature. It is also prone to warping and requires proper ventilation when printed.

Choosing the right filament for your project can be a challenging task, but understanding the properties and characteristics of each filament can help make the decision process easier. Consider the specific needs of your project, such as strength, flexibility, and detail, to determine which filament is best suited for your 3D printing needs.

Revolutionizing Manufacturing with 3D Printing Filaments: Industry Applications and Future Prospects

3D printing, also known as additive manufacturing, has been transforming various industries by revolutionizing the way products are created. The introduction of 3D printing filaments has further advanced this technology by allowing manufacturers to produce intricate designs and shapes, that were previously impossible or expensive to create.

Industry Applications

The applications of 3D printing filaments are vast, and they are being used in almost every industry today. Here are some notable examples:

Healthcare

3D printing filaments are being used extensively in the healthcare industry for the production of customized implants and prostheses. With this technology, medical professionals can create models of the patient’s specific anatomy and use it to design implants or customized prostheses. Additionally, medical professionals are using 3D printing filaments to print surgical tools and medical devices, saving costs and improving the accuracy of surgeries.

Aerospace

The aerospace industry has been an early adopter of 3D printing filaments for the production of lightweight yet strong parts. With the ability to print complex shapes, aerospace manufacturers can reduce the weight of aircraft parts without compromising their performance. This has resulted in cost savings and improved fuel efficiency for airlines.

Automotive

The automotive industry has also embraced 3D printing filaments, with manufacturers using the technology to produce prototypes, concept cars, and car parts. With 3D printing filaments, designers and engineers can create parts with intricate geometries and shapes, resulting in stronger and more efficient cars.

Future Prospects

The future of 3D printing filaments is bright, with new materials being developed and new technologies being created every day. Here are some potential future prospects:

Bioprinting

Bioprinting is an emerging field where 3D printing filaments are used to print living cells and create tissues and organs. With this technology, researchers and medical professionals can create personalized medicines and implantable organs that are tailored to individual patients.

Space Exploration

With the current advancements in technology, it is possible to print objects in space using 3D printing filaments. This technology would greatly enhance space exploration by allowing astronauts to produce necessary equipment and parts while on missions, rather than having to bring everything from Earth.

Sustainability

3D printing filaments have the potential to revolutionize sustainability efforts by allowing manufacturers to produce high-quality products with less waste. With this technology, manufacturers can recycle materials and use them to create new products, reducing the environmental impact of production processes.

Conclusion

3D printing filaments are transforming the manufacturing industry by allowing manufacturers to produce high-quality products with intricate shapes and geometries. With the plethora of materials available and the development of new technologies, the future of 3D printing filaments is bright, with endless possibilities for innovation and growth.

Filament Facts

Learn everything you need to know about filament for your 3D printer with these insightful facts

Product information

Product Review Score

4.6 out of 5 stars

68 reviews