3D printing has revolutionized the way we approach manufacturing, and it has become a popular technology in industries such as healthcare, aerospace, and education. One of the most popular 3D printing technologies is Fused Deposition Modeling (FDM).

FDM printers are affordable and easy to use, which makes them accessible to hobbyists, small businesses, and educational institutions. In this guide, we will explore the basics of FDM 3D printing, how it works, and its many applications.

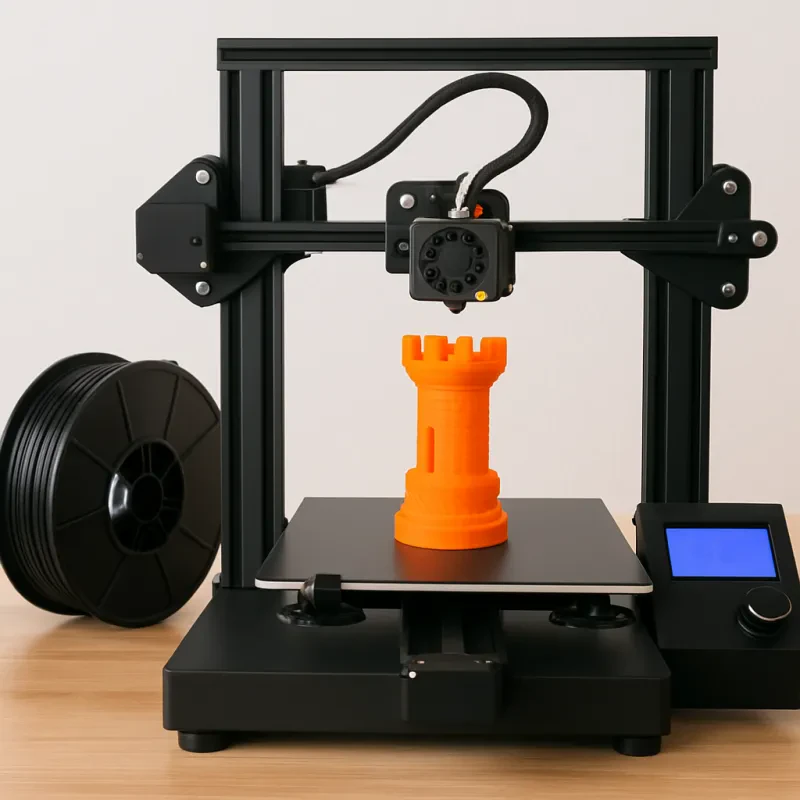

FDM 3D printing technology involves the creation of 3D objects through the deposition of melted plastic material, layer by layer, until the final object is formed. A plastic filament is fed into the printer through a spool and then melted by a heated nozzle. The molten plastic is then extruded onto a printing bed, creating the first layer of the object.

Once the first layer is complete, the printing bed slightly lowers, and the nozzle moves to create the second layer of the object. This process continues until the desired height and shape of the object is achieved. The printer then cools the object, and it's ready to be removed from the bed.

One of the advantages of FDM 3D printing is its versatility in using a wide range of materials, including ABS, PLA, Nylon, and carbon fiber. These materials offer various properties such as flexibility, strength, durability, and heat resistance, making it suitable for a range of applications.

FDM 3D printing technology also enables the creation of complex geometries and intricate designs that might be difficult to achieve using traditional manufacturing methods.

FDM 3D printers have a wide range of applications, including rapid prototyping, product design, architectural modeling, dental implants, medical devices, and educational models. With its ease of use, affordability, and versatility, FDM 3D printing technology is becoming an essential tool in modern manufacturing.

In conclusion, FDM 3D printing is an innovative technology that is transforming the way we approach manufacturing. Its versatility in using a wide range of materials and ability to create complex geometries and intricate designs make it an ideal tool for various applications. Through continuous innovation and development, FDM 3D printing technology will continue to push the boundaries of what's possible in modern manufacturing.

The Advantages and Disadvantages of FDM 3D Printing

When it comes to 3D printing, Fused Deposition Modeling (FDM) is one of the most widely used techniques. Here are some of the advantages and disadvantages of using FDM 3D printing:

Advantages

- Cost-effective: FDM 3D printers are more affordable compared to other types of 3D printers, making them a great option for individuals and small businesses who want to start using 3D printing technology.

- Easy to use: FDM 3D printers are user-friendly and easy to operate. They require minimal training, making them a great option for beginners and hobbyists.

- Large print volume: FDM 3D printers can handle large print jobs, making them ideal for creating big models, prototypes, and other large-scale objects.

- Wide variety of materials: FDM 3D printers support a wide range of materials including ABS, PLA, PVA, PETG, and more. This allows users to print objects with unique properties and finishes.

- Level of detail: FDM 3D printers are capable of producing objects with high precision and accuracy, making them ideal for creating functional prototypes and mechanical parts.

Disadvantages

- Quality of prints: FDM 3D printers may produce visible layer lines and rough textures, which may not be desirable for some applications.

- Slow printing speed: FDM 3D printers have a slower printing speed compared to other types of 3D printers, which can be a disadvantage when it comes to large and complex prints.

- Required support structures: In some cases, FDM 3D prints require support structures to be printed alongside the object, which can be time-consuming and add to the overall printing cost.

- Not perfect for intricate models: FDM 3D printers may not be the best option for printing intricate models with a lot of detail, as the layer lines may become more visible and challenging to remove during post-processing.

Overall, FDM 3D printing offers a cost-effective and versatile option for creating prototypes, models, and functional parts. However, it is important to consider the advantages and disadvantages before deciding if it is the best option for your specific needs.

Tips and Tricks for Getting the Most out of Your FDM 3D Printer

If you are new to 3D printing or just acquired your first FDM 3D printer, you may be unsure about how to maximize its capabilities. Here are some tips and tricks to help you get started:

1. Choose the Right Filament:

The filament that you use for your FDM 3D printer is crucial for obtaining high-quality prints. There is a range of filaments available in the market, each with its unique properties, such as temperature resistance, strength, and flexibility. To achieve the desired results, ensure you select the filament that matches your project's needs.

2. Level Your Build Plate:

Before you start printing, be sure to level your build plate. This step ensures that the nozzle is at the right distance from the print surface before printing begins, helping to prevent adhesion issues and other problems.

3. Use Support Structures Wisely:

Support structures are essential for printing complex geometries that cannot print without additional help. Use them intelligently to reduce the amount of material usage and save valuable printer time.

4. Regularly Clean Your Nozzle:

To ensure consistent material flow, periodically cleaning your nozzle is crucial, especially if you are using filaments that leave residue. Dirt buildup in the nozzle can lead to blockages, affecting print quality and ruining your printer altogether.

5. Experiment with Print Settings:

Each printer model has unique capabilities, and experimenting with the print settings can produce surprising results. Try adjusting parameters such as layer height, infill density, and print speed to produce your desired print.

6. Use a Build Enclosure:

An enclosure is beneficial when printing with temperature-sensitive filaments such as ABS. It helps regulate the ambient temperature and reduces the risk of warping or cracking.

7. Keep Your Printer in Optimal Condition:

A well-maintained printer performs best. Keep your printer clean and lubricated and ensure the firmware and software are up-to-date to avoid issues during the printing process.

By following these tips and tricks, you can get the most out of your FDM 3D printer and produce high-quality prints. Happy printing!

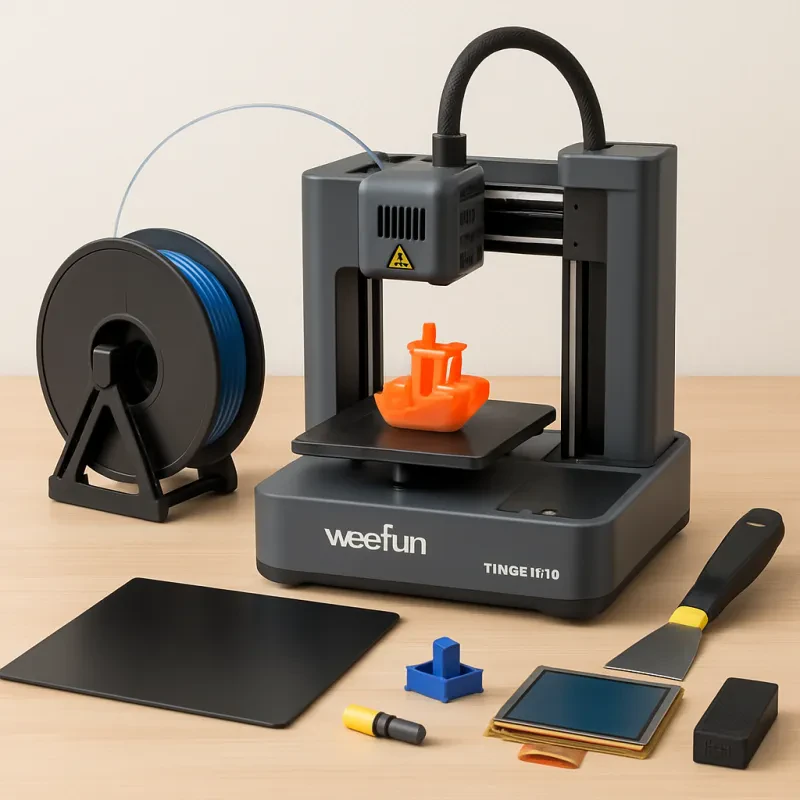

Mini FDM 3D Printer for Home Use

Bring Your Ideas to Life with High-Quality Mini FDM 3D Printer - Perfect for Home Use

Product information

Product Review Score

4.53 out of 5 stars

71 reviews